| Home |

| Contact-Us |

| Consultancy |

| Auditing |

| Software |

| Training |

| Case Study |

| Q & A |

| Resources |

| Downloads |

| Testimonials |

| Advertise |

| Links |

What is the Process Approach to Quality?

The ISO 9001 2000 standard is designed to manage and improve organizations processes. There is a great deal of misunderstanding and misinterpretation of the meaning of the process approach to Quality.

If you have at all been involved with quality assurance I am sure that you will at least heard of the "process approach" to Quality Assurance even if you are not fully aware of its meaning. The process approach to Quality Assurance is based on the idea that an organization is a system of interlinked processes.

If an organization does not define how its individual activities work together and the order in which the activities are performed it cannot deliver a quality product to its customers.

The process approach to quality involves analysing and then documenting the actual activities and links between those activities within an organization using simple process flowcharts. This technique is typically used by an auditor when conducting a gap analysis on a business. If you are unsure about your ability to identify your processes then you can employ a consultant to assist you.

Once the process and their interactions have been identified a framework of procedures and work instructions can be built around them.

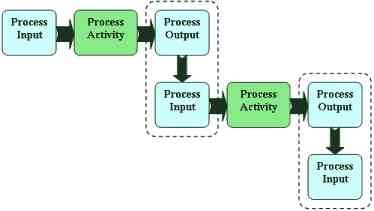

It can often be the case that the output from one process in an organization is the input for another process within the same organization. As can be seen in the diagram below where the output for activity one is the input for activity two and similarly the output of activity two is the input for activity three.

When analysing the processes within your organization it should be remembered that processes may link to processes outside of your organization. A typical example of this might be the product design interface between you and your customer.

Your organization sends a design concept to the customer (the Process input).

The customer approves the design (the Process activity).

You receive back the approved concept design (Process output)

In many organizations it may be possible to break down each process still further into their individual sub-process components, (please forgive the simplistic example).

For example: The posting of a letter might be broken down into.

Process 1: Selection of the envelope type. E.g. Padded, anti static, brown, white, anti-static.

Process 2: Selection of postal method. E.g. Courier, air-freight, secure, insecure.

Process 3: Selection of first or second class postage, same day, seven day.

Each of these processes can then be broken down into sub-processes. E.g. The closure of the envelope. Should it be the type you lick, self adhesive, secured with sticky tape, security fastener or wax seal?

One always has to look at the common sense approach as to how far you should break each process

down into sub-processes.

For example: If the customer does not specify the method of envelope seal to be used then any type of

seal may be used as long as it is fit for purpose. However, if the customer specifies a particular

type of seal for certain products the process becomes more important to both you and your customer

and therefore the process is worthy of documentation.

If you have difficulty documenting your processes, especially regarding the amount of detail required then it may be worth employing a consultant to guide you through the process. If your procedures are too prescriptive you will end up with unmanageable documents which serve no real purpose. A consultant will be able to minimise your documentation while ensuring compliance with ISO 9001 2000.

Many organizations already have documented instructions in the form of standard operating procedures (SOP's) and work instructions (WI's) that define how individual activities are performed. However, it is often the case that the interfaces between these instructions are misaligned. In some cases the interfaces are not even considered let alone documented. Misaligned process interfaces within an organisaton often leads to process fragmentation and eventually to break down of the organizations processes.

The ISO 9001 2000 standard has adopted the process approach to Quality management systems which is designed to improve an organizations processes.

The following rules may be used to implement a process approach to your Organizations Quality Management System.

| Identify your Organizations key processes. | |

| Define Quality Assurance levels for those processes. | |

| Decide how process quality will be measured. | |

| Document your approach to achieving the desired quality. | |

| Evaluate your quality level and continuously improve it. |

The following example will help guide you through the methology of identifying process inputs, activities and outputs.

As an example, let us consider the Purchasing Process:

1. The Input to the Purchasing process is a requirement to purchase materials, components or services.

2. The Purchasing Activity involves selecting a supplier from our approved supplier list and preparing a purchase order. We will interact with - The supplier: to place the order. - Receiving: to notify them of the material ordered. We may interact with - Engineering: if Purchasing specifications are needed. - Quality Assurance: if Receiving inspection is needed and to disposition the product if it is non-conforming when received.

3. The Output of the purchasing process is an approved purchase order released to the supplier.

A typical manufacturing company will have the following product realization processes:

| Customer Enquiry. | |

| Review and Quote. | |

| Receive Order | |

| Prepare Process Control Documentation | |

| Purchase Materials | |

| Receive Materials | |

| Production | |

| Pack | |

| Label and Ship |

In addition, we have the following support processes:

| Management Review | |

| Training | |

| Document Control | |

| Internal Auditing | |

| Corrective and Preventive Action |

Summary: As you develop your quality system, you must define the sequence and interaction of your processes in your quality manual as required in Section 4.2.2 of the new standard.

As you define your processes and prepare the accompanying documentation, be sure that the inputs, activities, interactions and outputs are fully defined so your quality system is effective.

This Article was Provided by a Driso Consultant.

Driso provide ISO 9001 2000

consultancy,

auditing,

software, and

training

Services.

They also supply Easy ISO 9001 2000® software for

initially setting up an ISO 9001 2000 compliant Quality Management System or improving upon an

existing one.

Click here to contact Driso Consultancy Services. See what they can

do for you and your business.

If you have an interesting ISO 9001 2000 article that you would like to publish on

this page to share with other like minded people please click on the [Submit Article].

Full recognition will be given to the author.

[Submit Article]